A production order is a document that specifies the name and number of units to be produced, location where production has to be done, date of production, and the quantity of components (input products) required.

To create a production order you must have already set the products (both those to be produced and the input products) and the warehouse where the production will occur.

Since the result of a production order is to write off, from the inventory of input goods and materials, and increase the amount of goods and materials produced, the production order is one of the types of inventory adjustments.

It is important to note that all the input products must be accounted for in one warehouse. To the same warehouse, once the production order is confirmed, the items produced will be added.

Follow the steps below to enter a production order into the program:

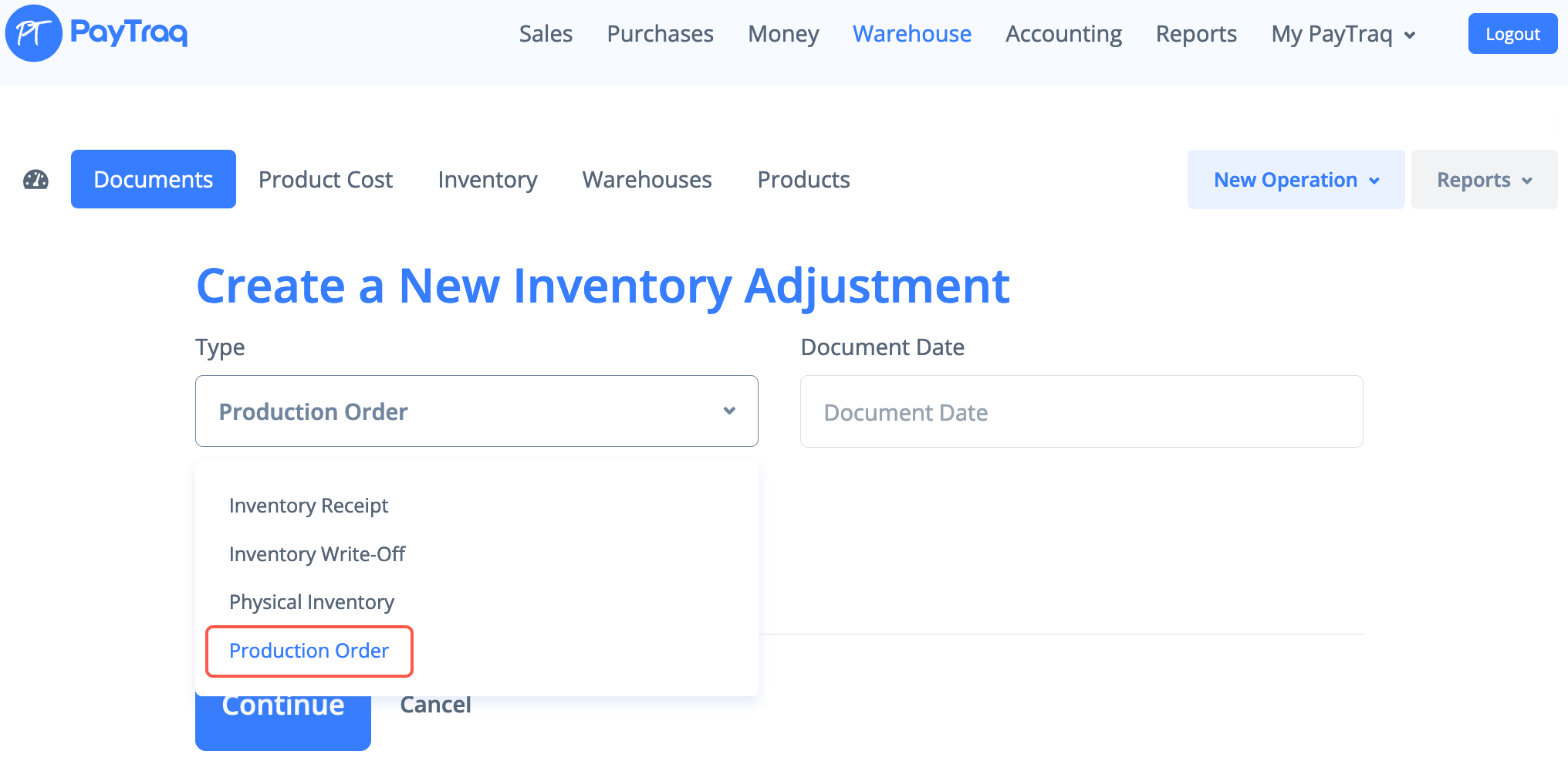

1) Select the menu Warehouse -> New Operation -> Enter an Inventory Adjustment.

2) Select the adjustment type: Production order.

3) Enter the date, select the warehouse. Click on “Continue” button.

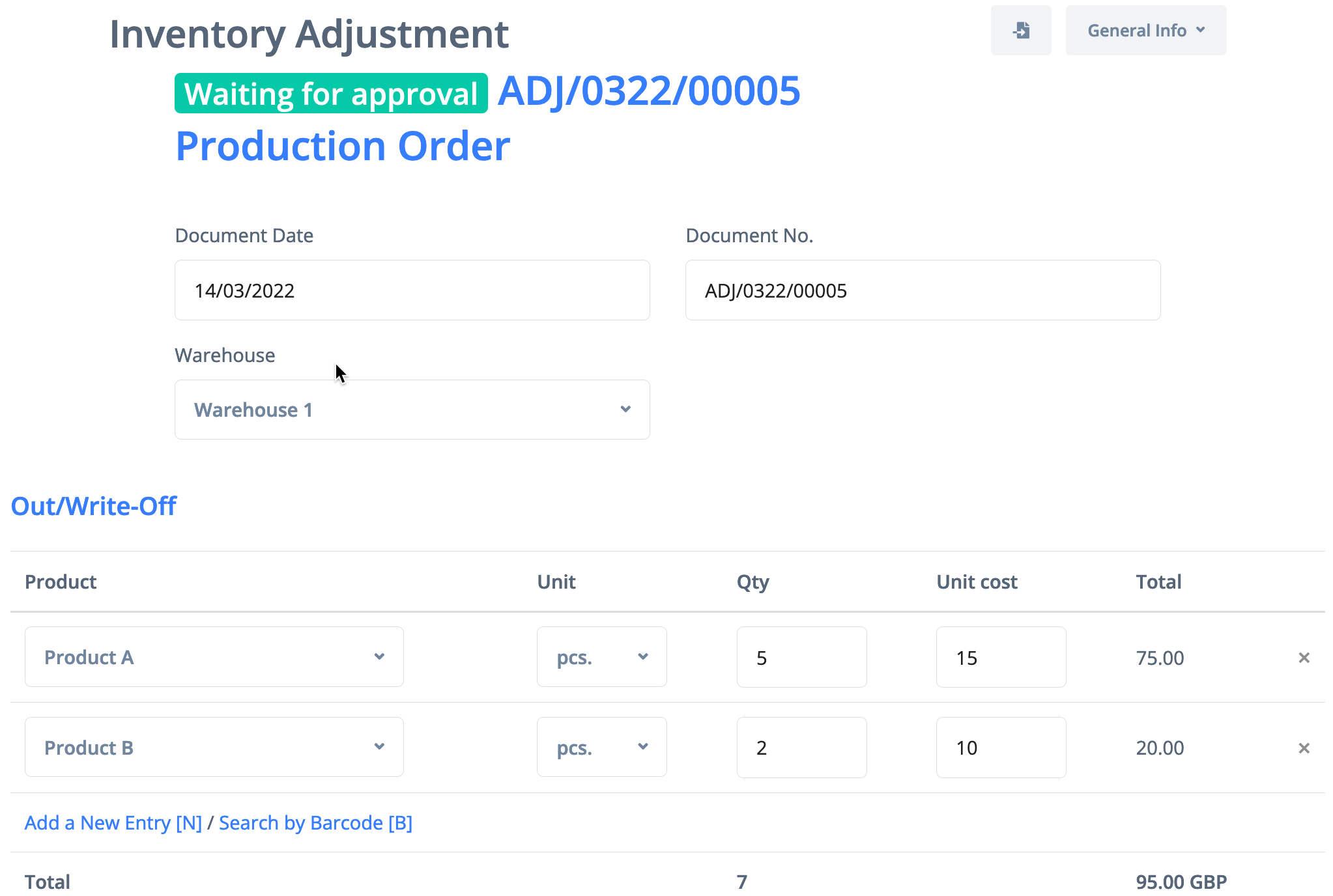

4) In the window that opens, add to the list of items those products that will be used (written off) in the execution of a production order and their quantity.

When you add an item to the list, its actual calculated cost will be written in the "Unit cost" field. If needed, its value can be edited manually.

To add a new line, press the “N” key on the keyboard or click the “Add a New Entry” link. Having completed the list press “Update” to save the entered information.

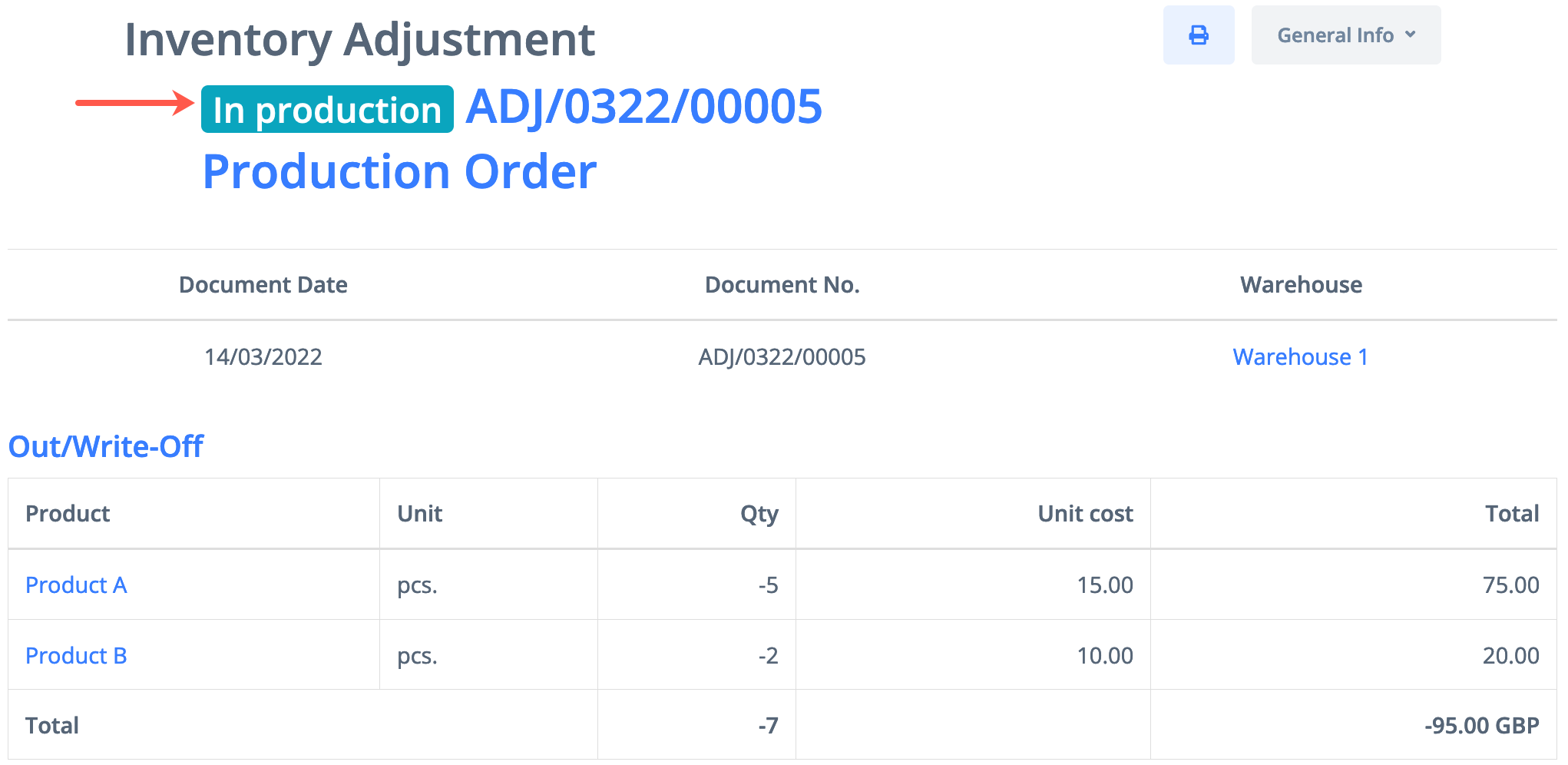

5) Check the list of the input items (Out/Write-Off list) and click on “Approve” button. The input items are written off from the inventory. The production order is now saved with a status of “In Production”.

6) Then click the “Receive" button to create a list of produced items.

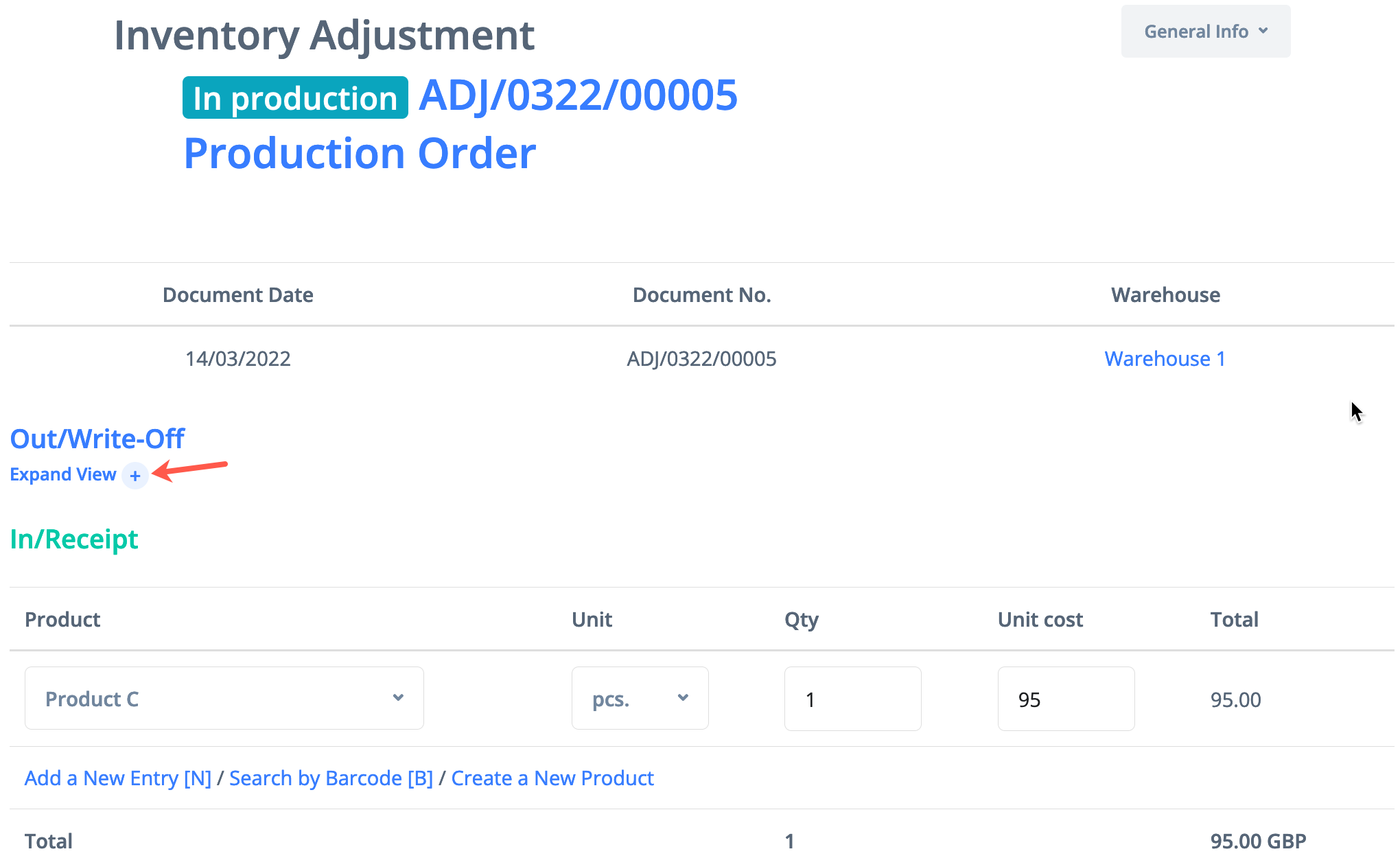

7) In the window that opens add to the list all produced items, their quantities, and cost per unit.

If you click on the "+" sign, you can also see the list of input items, which you have formed in the previous step.

Having completed the In/Receipt list, press the “Update” button.

8) Check the list of the produced items. At this stage, if necessary, you can still edit the list of received items by pressing the "Receive" button on top.

After making sure that the production order is created correctly, click the “Mark as Done” button.

The produced items will be added to the warehouse inventory and the whole operation will be completed.